RX II

GCC RX II Vinyl Cutter

The brand new RX II series of cutting plotters is available in four sizes, 61cm, 101cm, 132cm, and 183cm, which are among the best models for higher blade pressure, faster-cutting throughput, and precision of long tracking compared to same class models. Designed With a stylish appearance and new functional features, the RX II series is the top notch cutter in the market for professional sign makers.

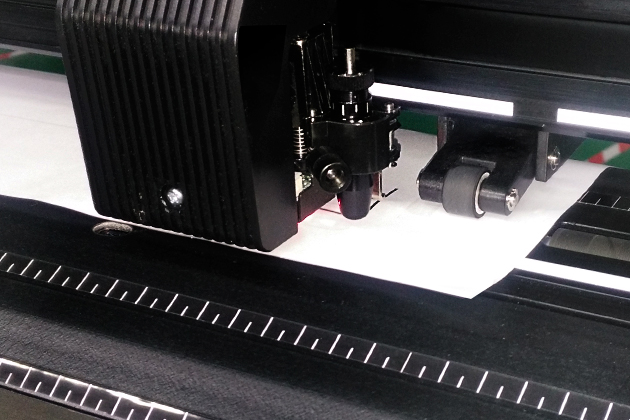

Creasing Ability (only for creasing model)

Equipped with the dual tool holders with creasing tool and blade, RX II creasing model offers cardstock creasing and cutting to make small volume of paper box. PS. It’s suggested that the cardstock weight range is 200 to 350 gsm, and the weight will vary with the type and thickness of paper.

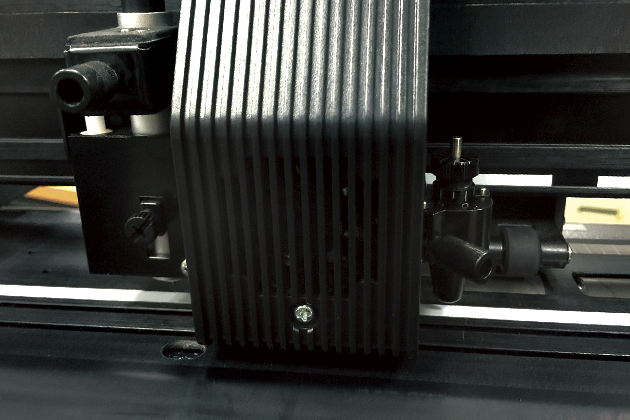

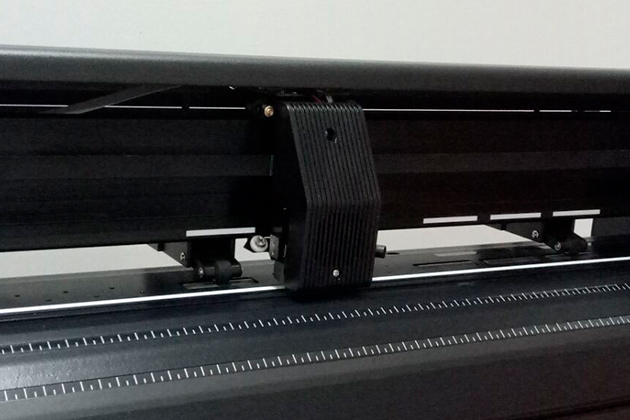

Dual Tool Holder (creasing model only)

Equipped with special dual holder – blade holder and creasing tool holder – on the carriage, creasing lines and cut lines can be made at one time. It saves your valuable time.

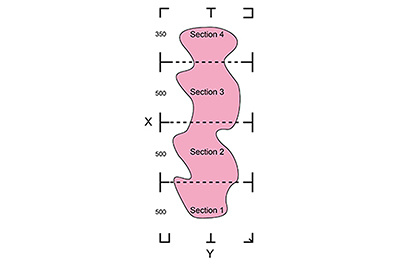

Section Cutting

Section cutting divides the long plot data into sectional output jobs to gain higher cutting quality and increase precision. GCC RX II series scan registration mark of section 1 and cut the plot data in section 1, and then it scan registration mark of section 2 and cut the plot data in section 2, and so on.

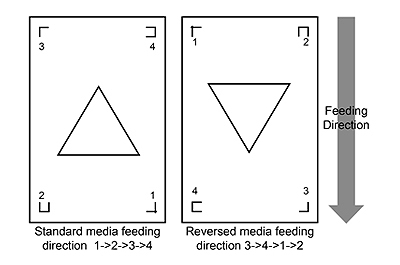

Auto Rotation

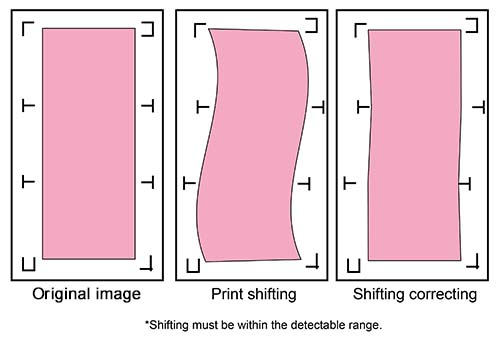

Segmental Positioning

RX II series features Segmental Positioning function which can correct the crooked print. Printed image may be crooked because the printing shifts, and Segmental Positioning function can scan the registration marks one by one automatically to calibrate shift.

Enhanced AAS II Contour Cutting System

The RX II series features a standard Automatic-Aligning System (AAS II) to guarantee precise contour cutting by automatically detecting the registration marks on digitally produced images.

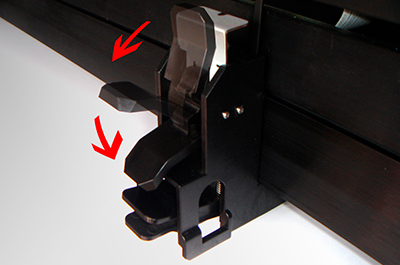

Multiple Pressure Pinch Rollers for Different Media

| Materials | Left side | Middle | Right side |

| Sandblast mask, Reflective film | Heavy | Medium | Heavy |

| Vinyl | Medium | Medium | Medium |

| Window tinting film | Medium | Light | Medium |

Triple Port Connectivity

RX II series supports triple port connectivity with USB, serial and Ethernet ports. The USB port provides faster and convenient data transmission between the computer and RX II. Ethernet connection enables multiple RX II to be operated by one PC and multiple PCs to share a single unit. Triple port connectivity provides sign makers a great flexibility for data transmission.

Auto Cut Off

This features allows users to set the cutter to cut off the media after the completion of each job, making it easy to set up an unattended workflow for mass production. Or user can simply push the “Cut off” button after the completion of a job to have the media cut off automatically.

Touch Key Panel & Backlight LCM

Efficient Throughput

At up to 60 inches per second of cutting speed, RX II series cutting throughput simply outperforms the competition.

600 Grams of Cutting Force

Selectable cutting forces, ranging from 5 to 600g, accommodate a wide variety of materials, including fine and thin masking films to thick and hard reflective films.

Innovative Tangential Mode

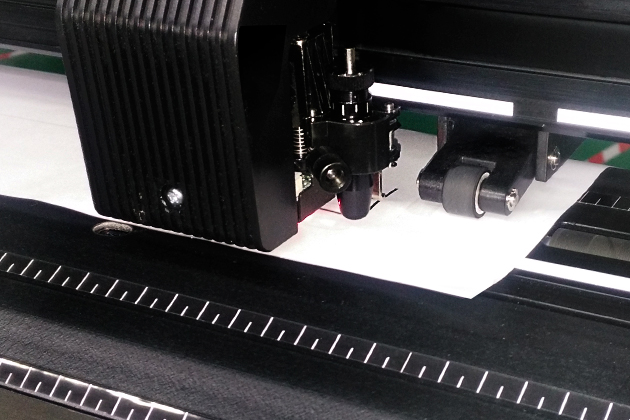

Media Support System

The media support system is fully adjustable. It supports media on standard cores and resolves media drifting and alignment problems to ensure better tracking.

Handy Grooved Cut Off Tool

This handy and innovative design allows you to cut off a finished job in a straight line easily, reducing the possibility of wasting usable material.

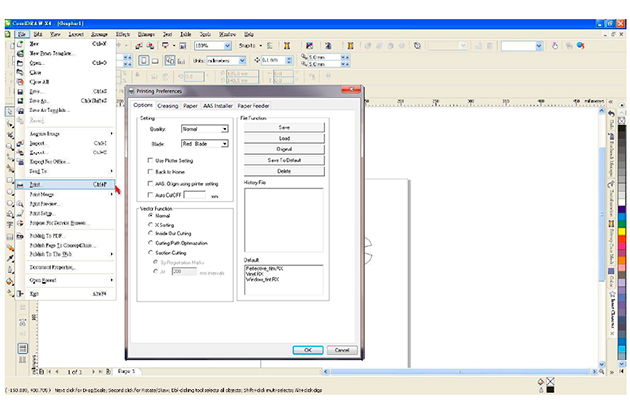

Advanced One Click Driver

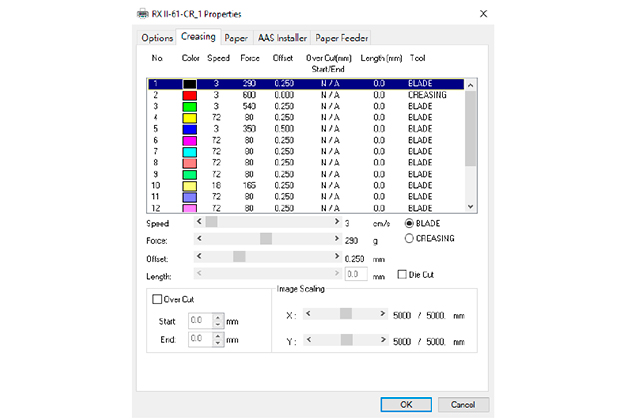

Multiple Parameters Setting by 16 Different Colors

The new interface allows users to set up multiple parameters by using different color lines. This gives the operator greater flexibility when setting up a job.

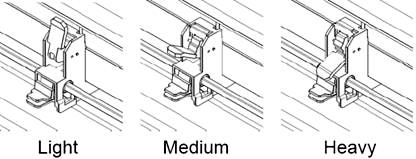

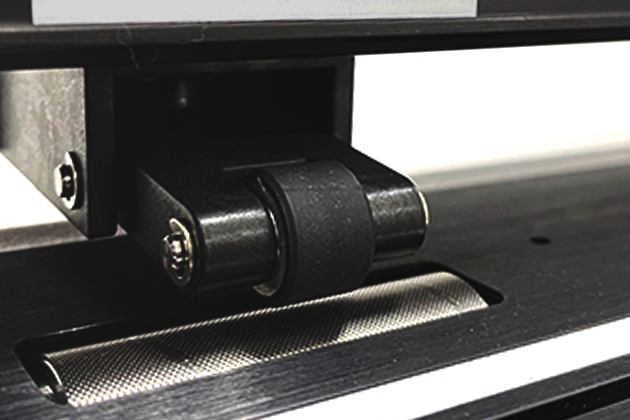

Selective Pinch Roller Positioning

Each pinch roller can be positioned and operated individually, widening the RX II series cutting plotters’ range of applications.

Guaranteed 10m Tracking Ability

RX II Technical Data

| RX II - 61 (Creasing) | RX II - 61 | RX II - 101S | RX II - 132S | RX II - 183S | |

|---|---|---|---|---|---|

| Operational Method | Roller-Type | Roller-Type | Roller-Type | Roller-Type | Roller-Type |

| Max. Cutting Width | 536mm | 610mm | 1010mm | 1320mm | 1830mm |

| Max. Cutting Length | 50m | 50m | 50m | 50m | 50m |

| Max. Media Loading Width | 642mm | 810mm | 1326mm | 1635mm | 2145mm |

| Min. Media Loading Width | 50 mm | 50 mm | 50 mm | 50 mm | 50 mm |

| Number of Pinch Rollers | 3 | 3 | 3 | 4 | 5 |

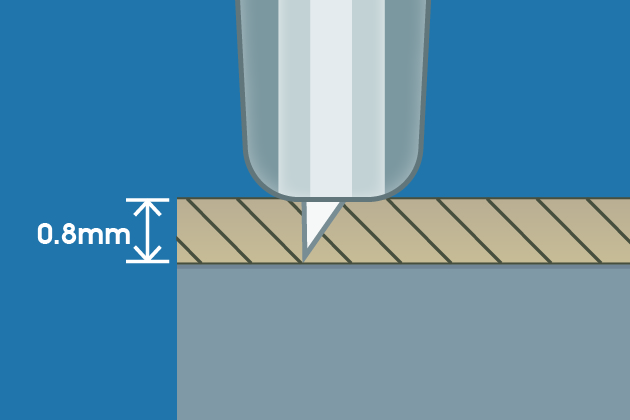

| Acceptable Material Thickness | 0.8 mm | 0.8 mm | 0.8 mm | 0.8 mm | 0.8 mm |

| Driver | DC Servo Control | DC Servo Control | DC Servo Control | DC Servo Control | DC Servo Control |

| Max. Cutting Force | 600g | 600g | 600g | 600g | 600g |

| Max. Cutting Speed | 1530 mm/sec (60 ips) (at 45° direction) | 1530 mm/sec (60 ips) (at 45° direction) | 1530 mm/sec (60 ips) (at 45° direction) | 1530 mm/sec (60 ips) (at 45° direction) | 1530 mm/sec (60 ips) (at 45° direction) |

| Acceleration | 4.2 G (gravity) | 4.2 G (gravity) | 4.2 G (gravity) | 4.2 G (gravity) | 4.2 G (gravity) |

| Offset | 0~1.0 mm (with an increase of 0.025mm) | 0~1.0 mm (with an increase of 0.025mm) | 0~1.0 mm (with an increase of 0.025mm) | 0~1.0 mm (with an increase of 0.025mm) | 0~1.0 mm (with an increase of 0.025mm) |

| Memory Buffer | 32 MB /16 MB (when using AAS) | 32 MB /16 MB (when using AAS) | 32 MB /16 MB (when using AAS) | 32 MB /16 MB (when using AAS) | 32 MB /16 MB (when using AAS) |

| Interfaces | USB 2.0 (Full Speed) and Serial (RS-232), and Ethernet | USB 2.0 (Full Speed) and Serial (RS-232), and Ethernet | USB 2.0 (Full Speed) and Serial (RS-232), and Ethernet | USB 2.0 (Full Speed) and Serial (RS-232), and Ethernet | USB 2.0 (Full Speed) and Serial (RS-232), and Ethernet |

| Type of Command | HP-GL, HP-GL/2 | HP-GL, HP-GL/2 | HP-GL, HP-GL/2 | HP-GL, HP-GL/2 | HP-GL, HP-GL/2 |

| Mechanical Resolution | 0.006 mm | 0.006 mm | 0.006 mm | 0.006 mm | 0.006 mm |

| Software Resolution | 0.025 mm | 0.025 mm | 0.025 mm | 0.025 mm | 0.025 mm |

| Distance Accuracy | ±0.254 mm or ±0.1% of move, whichever is greater | ±0.254 mm or ±0.1% of move, whichever is greater | ±0.254 mm or ±0.1% of move, whichever is greater | ±0.254 mm or ±0.1% of move, whichever is greater | ±0.254 mm or ±0.1% of move, whichever is greater |

| Repeatability | ±0.1 mm | ±0.1 mm | ±0.1 mm | ±0.1 mm | ±0.1 mm |

| Automatic-Aligning System | Completely Automatic Contour Cutting System for print to cut solution | Completely Automatic Contour Cutting System for print to cut solution | Completely Automatic Contour Cutting System for print to cut solution | Completely Automatic Contour Cutting System for print to cut solution | Completely Automatic Contour Cutting System for print to cut solution |

| Auto Rotation | Yes | Yes | Yes | Yes | Yes |

| Section Cutting | Yes | Yes | Yes | Yes | Yes |

| Curve & Arc Smoothing | Yes | Yes | Yes | Yes | Yes |

| Configurable Origin | Yes | Yes | Yes | Yes | Yes |

| Test Cut Capability | Yes | Yes | Yes | Yes | Yes |

| Tangential Mode | Yes | Yes | Yes | Yes | Yes |

| Over Cut | Yes | Yes | Yes | Yes | Yes |

| Repeat | Yes | Yes | Yes | Yes | Yes |

| Copy | Yes | Yes | Yes | Yes | Yes |

| Control Panel | LCD (20 digits x 2 lines), 15 Keys, 1 Power LED, 1 Green LED | LCD (20 digits x 2 lines), 15 Keys, 1 Power LED, 1 Green LED | LCD (20 digits x 2 lines), 15 Keys, 1 Power LED, 1 Green LED | LCD (20 digits x 2 lines), 15 Keys, 1 Power LED, 1 Green LED | LCD (20 digits x 2 lines), 15 Keys, 1 Power LED, 1 Green LED |

| Diameter of Blade | 2.5 mm | 2.5 mm | 2.5 mm | 2.5 mm | 2.5 mm |

| Stand | Optional | Optional | Standard | Standard | Standard |

| Media Basket | Optional | Optional | Optional | Optional | Optional |

| Power Supply | 100~240 VAC 50 / 60 Hz (auto switching) | 100~240 VAC 50 / 60 Hz (auto switching) | 100~240 VAC 50 / 60 Hz (auto switching) | 100~240 VAC 50 / 60 Hz (auto switching) | 100~240 VAC 50 / 60 Hz (auto switching) |

| Power Consumption | Max. 250 W | Max. 250 W | Max. 250 W | Max. 250 W | Max. 250 W |

| Dimension (H x W x D) mm | 437 x 1098 x 479 | 437 x 1098 x 479 | 1147 x 1614 x 651 | 1147 x 1923 x 651 | 1147 x 2433 x 756 |

| Net Weight | 25.5kg | 25kg | 61.8kg | 71.5kg | 82kg |

| Operation Environment - Temperature | 15° C~30° C | 15° C~30° C | 15° C~30° C | 15° C~30° C | 15° C~30° C |

| Operation Environment - Humidity | 25% ~ 75% | 25% ~ 75% | 25% ~ 75% | 25% ~ 75% | 25% ~ 75% |

Our mission is to support and empower people who are seeking to make their mark through the endless possibilities of laser technology.

Uscribe is focused on helping you ‘make your mark’ through the amazing possibilities of laser technology.