Spirit-Series Lasers

GCC LaserPro Spirit-Series

The GCC Spirit Series has received worldwide accolades from the signs and awards industry for laser engraving since its introduction. GCC LaserPro users always have an edge over the others with numerous uniquely innovative and user friendly features

RoHS Compliance

All GCC laser engravers are RoHS-compliant (the European Parliament Directive 2002/ 95/ EC, Restriction of Hazardous Substances) and lead-free (pb free). GCC will continue to concern and provide eco-friendly products to protect the earth for our further generations.

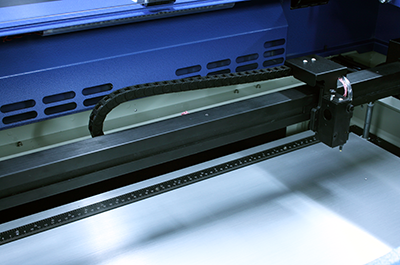

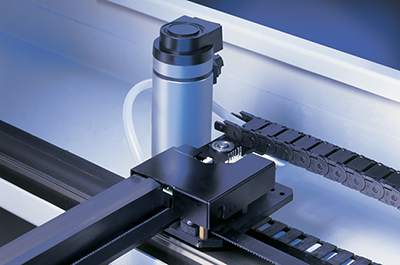

DuraGuide Motion Design

Systematic and reliable motion system embedded with strong mechanical framework and accurate servo motor control technology to deliver superb laser engraving output quality under rapid movement.

DC Servo Motor

Spirit-Series laser engravers utilizes Closed-loop DC servo motor that delivers greater continuous shaft power at higher speeds than a stepper of the same frame size. In addition, It can also give far greater accuracy for laser engraving due to the continuous movement, instead of constant stopping and starting.

TrueImage™ Engraving Technology (Patented)

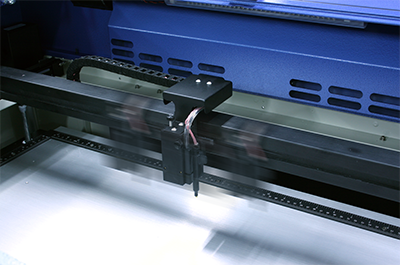

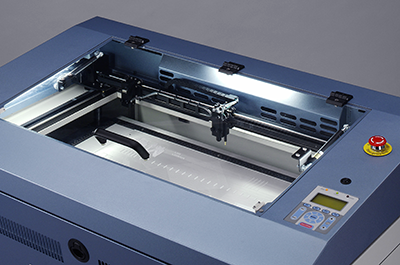

Rigid and Reliable Construction

Rigid and stable chassis construction of the laser engraver ensures consistent output quality under high speed movement.

Programmable Origin Modes

Easy-to-use multiple position modes allow the operators an effortless way to set up laser engraving jobs with Drag-N- Play. Repetitive workflows can be drastically simplified by relocating the origin position to any desired location.

SmartCENTER™ (Patented)

The super user-friendly SmartCENTER™ function helps end users to easily and automatically locate the center point of objects of any shape vastly eliminating tedious setup time.

SmartACT™ (Patented)

Spirit series laser engraver SmartACT™ is a ground-breaking technology that reduces the ramping process and job running time for laser engraving, which translates into higher productivity.

SmartLID™ (Patented)

An innovative lid that opens from both ends of the laser engraver allows easy access for daily maintenance.

Key Switch & Emergency Stop

Key switch safeguards the laser engraver from unauthorized use. Prominent emergency button located on the top of the machine allows operators to stop the laser and the motion carriage immediately to provide a safe operating environment.

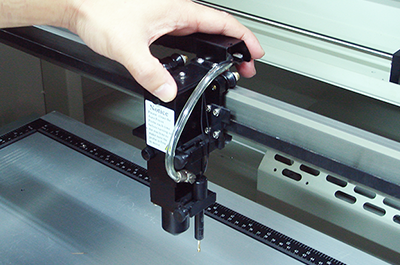

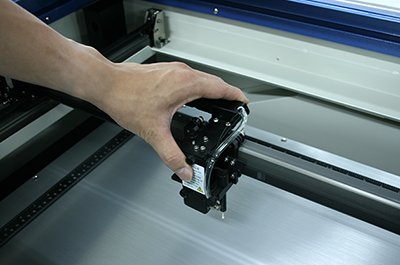

SmartPIN™ AutoFocus (Patented)

The plug-and-play probe design makes focusing a one-touch process and provides the accuracy and precision required for optimum quality even when laser engraving on transparent materials.

Intuitive Control Panel Interface

A control panel with coherent hot-key design and graphical icon displays that allows you to change laser engraving parameter settings, set jobs to repeat unlimited times, queue jobs, delete jobs, and more.

SmartLIGHT

A Built-in LED light module illuminates the working space of the laser engraver and makes every laser engraving detail easy to see.

Drag-N-Play

QSM

Quality-Speed-Mode technology redefines the correlation between speed and quality allowing the generation of marvelous laser engraving quality while racing at high speeds.

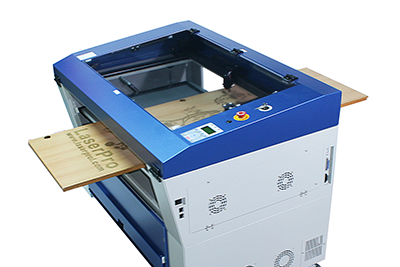

Pass-through Front to Rear Doors (Optional)

A design with doors on both ends of the laser engraver to accommodate extremely long working pieces without the need for a screwdriver.

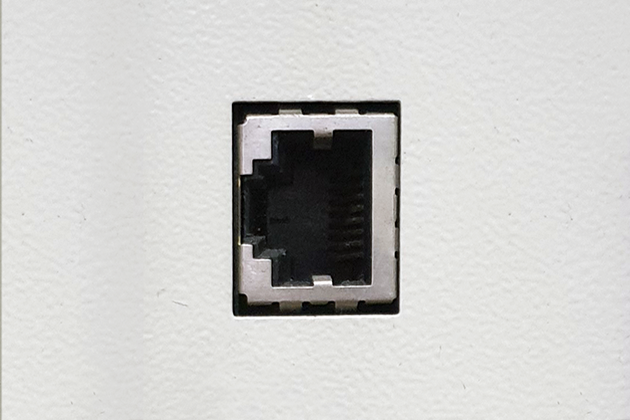

Built-In Networking Connection

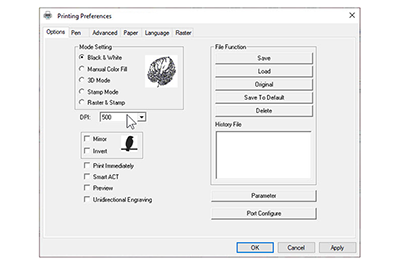

Innovative Windows Driver

Directly output from familiar designing software like Illustrator, CorelDraw, AutoCad through GCC LaserPro Windows driver for laser engravers. The innovative driver features SmartCENTER, Air Assist by Pen, Defous by Pen, Bridge Cutting, Drill, Dithering Patterns, and more to reduce set up time and make easy adjustments to achieve marvelous output quality.

Spirit Series Technical Data

| Spirit LS | Spirit GLS | Spirit GLS Hybrid | |

|---|---|---|---|

| Laser Source | 12 to 100W 10.6-μm sealed CO2 Laser / 20W & 60W 9.3-μm sealed CO2 Laser | 30 to 100W 10.6-μm sealed CO2 Laser / 20W & 60W 9.3-μm sealed CO2 Laser | Dual (CO₂+Fiber) |

| Laser Cooling | Air-cooled, Operating environment temperature 15°-30°C | Air-cooled, Operating environment temperature 15°-30°C | Air-cooled, Operating environment temperature 15°-30°C |

| Working Area | 640 x 460 mm Extendable to 740 x 460 mm | 860 x 610 mm Extendable to 960 x 610 mm | 860 x 610mm Extendable to 965 x 610 mm |

| Max. Part Size (L x W x H) All Doors Closed | 762 x 482.6 x 165 mm | 990 x 635 x 177 mm | 990 x 635 x 177 mm |

| Dimensions | 1125 x 720 x 1005 mm | 1365 x 880 x 1010 mm | 1365 x 880 x 1010 mm |

| Driving Motor | Closed-loop DC servo control | Closed-loop DC Servo Control | Closed-loop DC Servo Control |

| Maximum Motor Speed | 80 IPS | 80 IPS | 80 IPS |

| Speed Control | Adjustable from 0.1~100% ( Up to 16 color-linked speed settings per job ) | Adjustable from 0.1~100% ( Up to 16 color-linked speed settings per job ) | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) |

| Power Control | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | Adjustable from 0~100% (Up to 16 color-linked power settings per job) | Adjustable from 0.1~100% (Up to 16 color-linked speed settings per job) |

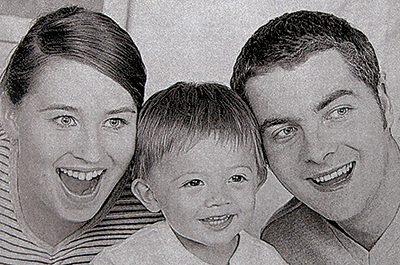

| Engraving Capability | 256-level gray scale image processing capability | 256-level gray scale image processing capability | 256-level gray scale image processing capability |

| Distance Accuracy | 0.254 mm or 0.1% of move, whichever is greater | 0.254 mm or 0.1% of move, whichever is greater | 0.254 mm or 0.1% of move, whichever is greater |

| Resolution (DPI) | Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500 | Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500 | Available 125, 250, 300, 380, 500, 600, 760, 1000, 1500 |

| Z-Axis Movement | Automatic | Automatic | Automatic |

| Focus Lens | Standard 2.0", optional 1.5", 2.5", & 4.0" available | Standard 2.0", optional 1.5", 2.5", & 4.0" available | Standard 2.0" (Optional 3.0" &4.0") |

| Interface | 10 Base-T Ethernet USB Type-A 2.0 – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0 – For connecting with the computer | 10 Base-T Ethernet USB Type-A 2.0 – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0 – For connecting with the computer | 10 Base-T Ethernet USB Type-A 2.0 – For USB storage (Max. 32GB capacity, FAT file system) USB Type-B 2.0 – For connecting with the computer |

| Display Panel | 4-line LCD : panel showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus | 4-line LCD display showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus | 4-line LCD display showing current file name, total working time, laser power, engraving speed, file(s) loaded into memory buffer, setup and diagnostic menus |

| Safety | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module | Class I Laser Product Compliant with EN60825 Class II Laser Product Compliant with CDRH 2006/42/EC Machinery Directive Compliance Class 4 Laser Product Compliant with CDRH with the optional pass-through door module |

| Operation Voltage | Laser below 80Watt, 100-240VAC, 50-60Hz Auto Switching, Max. 15A Laser 80Watt and above, 200-240VAC, 50-60Hz, Max. 15A | Laser below 80Watt, 100-240VAC, 50-60Hz Auto Switching, Max. 15A Laser 80Watt and above, 200-240VAC, 50-60Hz, Max. 15A | Below 80Watt, 100-240VAC, 50/60HZ Auto Switching, max. 15A 80Watt and above, 200-240VAC, 50/60HZ Auto Switching, max. 15A |

| Fume Extraction System | External exhaust system with minimum flow rate 640m3/h (CFM 377 ft3/min) is required,2.3kPA negative pressure (Pure-Air PA-1000FS @ 4" exhaust port) | External exhaust system with minimum flow rate 800m3/h (CFM 471 ft3/min) is required,2.3kPA negative pressure (Pure-Air PA-1500FS @ 4" exhaust port) | External exhaust system with minimum flow rate 800m3/h (CFM 471 ft3/min) is required,2.3kPA negative pressure (Pure-Air PA-1500FS @ 4" exhaust port) |

Our mission is to support and empower people who are seeking to make their mark through the endless possibilities of laser technology.

Uscribe is focused on helping you ‘make your mark’ through the amazing possibilities of laser technology.