What you need to know about laser focus lenses

HOW IT ALL WORKS

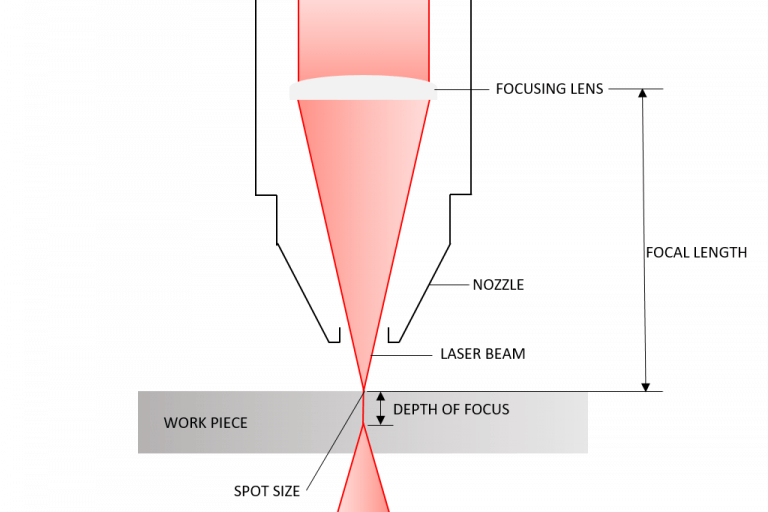

A focus lens in a Co2 laser cutter/engraver converges the laser beam to create a focus point where the laser is cutting or engraving the material. This point is at the sharpest convergence of the beam, and is commonly referred to as the ‘spot size’. Several factors affect this spot size, which will ultimately determine the outcome of your project. This article intends to illustrate these differences and give you a deeper understanding on which lens is most appropriate for you.

WHAT ARE THE DIFFERENT OPTIONS?

The most common lens options are 1.5, 2.0, 3.0 and 4.0 inch. These measurements refer to the focal length (see diagram), required for each lens to be perfectly in focus. For example, a 1.5” lens needs to be precisely 1.5” above the face of the material to be properly focused. The main factors differentiating each lens, is spot size and depth of focus. The smaller lens, the smaller the focal length and spot size.

WHAT DIFFERENCE DO THEY MAKE, AND WHICH ONE DO I NEED?

A smaller lens allows for finer resolution when engraving. However, smaller lenses have a reduced depth of focus, causing decreased cutting capacity and are only recommended for cutting thin materials. The larger the lens, the larger the spot size and depth of focus, increasing the cutting capability. Larger lenses are recommended for cutting thick materials and cutting at increased speeds. However, the larger the lens the more you will be sacrificing engraving resolution. The spot size also effects beam energy, which is why a larger lens requires a higher wattage laser. Most laser cutter/engraver systems will come standard with a 2 inch lens as this gives the best overall performance, with a balance of good engraving resolution and cutting capability. See overview below.

1.5 inch lens:

– Highest resolution

– Best for cutting thin materials and engraving small detail

– Easiest to fall out of focus

2.0 inch lens:

– Best overall, a good compromise of focus sharpness and depth of etching

– Can cut materials of relative thickness, with appropriate laser power input

– Mostly used for engraving

3.0 inch lens:

– Best for cutting thicker materials such as timber and acrylic

4.0 inch lens:

– Largest depth of focus

– Best used for cutting thick materials or engraving materials with curvature

– Very large spot size requires high power lasers.

About Us

Our mission is to support and empower people who are seeking to make their mark through the endless possibilities of laser technology.

Uscribe is focused on helping you ‘make your mark’ through the amazing possibilities of laser technology.

Get all the Latest News, Specials & Advice.

Copyright © 2022 Uscribe laser systems